- I. What is benefits after you use YELOCO Transformer oil filtering machine?

YELOCO Series YH-ZYD Double-stage vacuum Transformer Oil Filtering Machine is special for purification:

- Transformer oil

- Insulating oil

- Cable oil

- Silicone oil

- Dielectric oil

- Mutual Inductor oil

- Switch oil

YELOCO Series YH-ZYD Double-stage vacuum Transformer Oil Filtering Machine can remove the water, gas and impurities in transformer oil high-efficiently, increasing and maintain the oil’s dielectric strength and quality of oil, make sure the electric device running safely.

Series YH-ZYD Double-stage vacuum Transformer Oil Filtering Machine is mainly used to improve the properties of transformer oil for 66KV to 500KV power transmission project. It can remove trace water, gas, particulate matters, etc. from the insulating oil effectively and rapidly so as to boost the performance of transformers, circuit breakers, mutual inductors, cable and capacitors which have an insulation system.

After YELOCO Series YH-ZYD Double-stage vacuum Transformer Oil Filtering Machine treatment, the oil data as below:

- Breakdown Voltage ≥75KV after one-time treatment

- Water Content ≤3PPM after one-time treatment

- Gas Content ≤0.1% after one-time treatment

- Filtering Precision is 1μm

- Acetylene gas content is 0

Series YH-ZYD Double-stage vacuum Transformer Oil Filtering Machine can be used as independent vacuum source with functions of vacuum drying, vacuum filling oil.

II. How to choose suitable flow capacity Transformer oil filtering machine?

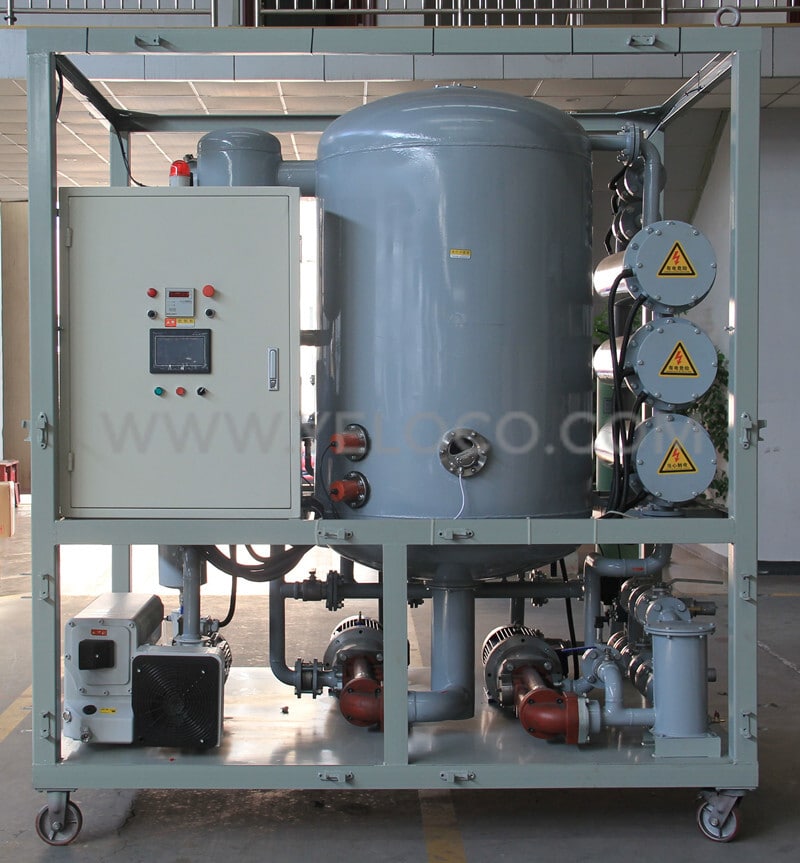

1800Liters/ Hour, 2000Liters/Hour, 3000Liters/Hour Double-stage vacuum Transformer Oil Filtering Machine reference picture

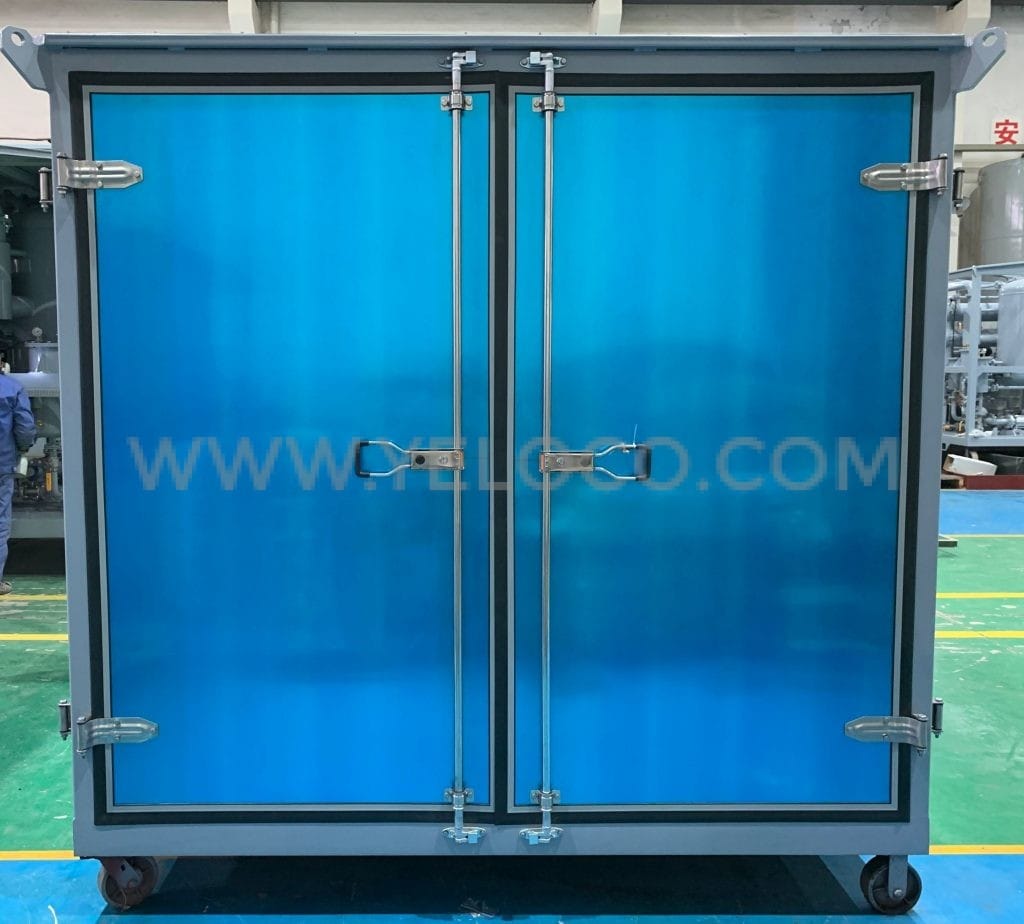

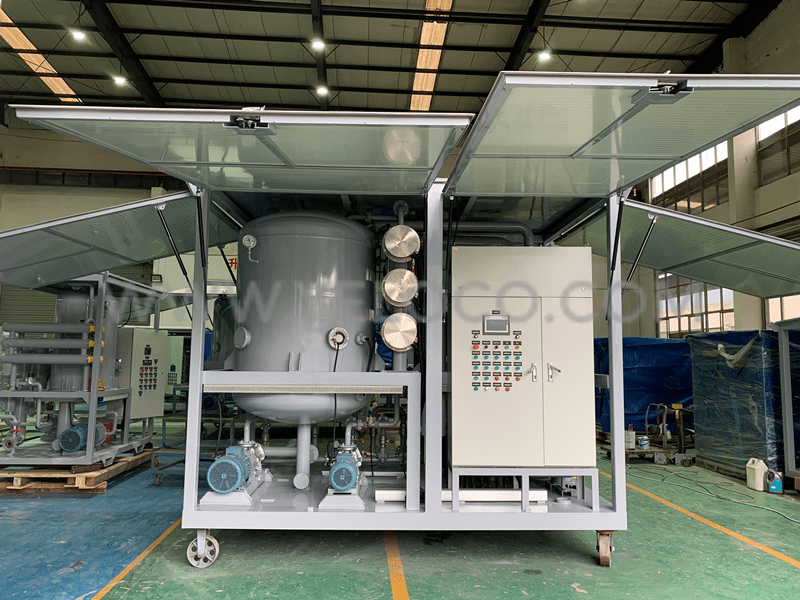

6000Liters/Hour Double-stage vacuum Transformer Oil Filtering Machine reference picture

6000Liters/Hour Double-stage vacuum Transformer Oil Filtering Machine reference picture

9000Liters/Hour Double-stage vacuum Transformer Oil Filtering Machine reference picture

12000Liters/Hour Double-stage vacuum Transformer Oil Filtering Machine reference picture

18000Liters/Hour Double-stage vacuum Transformer Oil Filtering Machine reference picture

- III. Why choose YELOCO Transformer oil filtering machine?

- 1. Stable and reliable quality. Our factory make oil filtering machine more than 20years. We have advanced technology and rich experience to guarantee high quality oil filtering machine to customers.

- 2. Complete models to meet all customer needs.

YH-ZY High Vacuum Transformer Oil Purifier Machine

YH-ZYD Double-stage Vacuum Transformer Oil Filtering Machine

YH-ZYD-A Fully Automatic Double-stage Vacuum Transformer Oil Filtering Machine

YH-ZYD-E Enclosed type Double-stage Vacuum Transformer Oil Filtration Machine

YH-ZYD-M Mobile type Double-stage Vacuum Transformer Oil Purification Machine

We also make machine according to your special requirements.

- 3. Low maintenance cost. Because we use the every parts are best quality parts, the use life is very long. It will help customers save more maintenance cost and time.

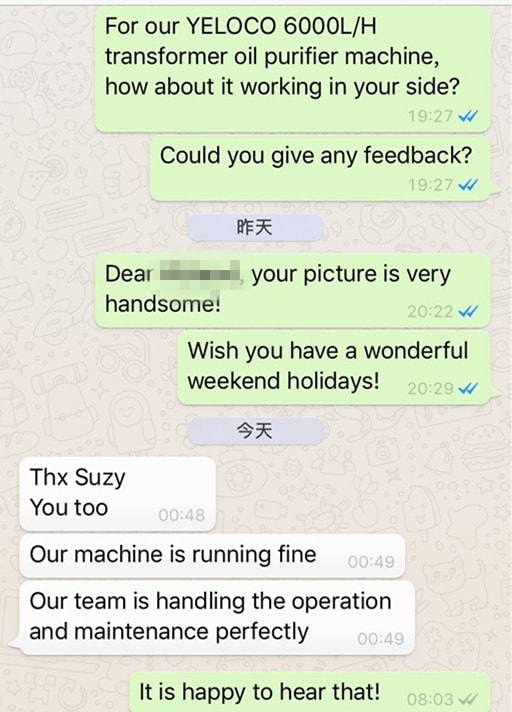

- 4. Our products and services have won unanimous praise from customers.

- 5. Detail operation videos to show how to operate step by step. Solve customers’ concerns about not being able to operate.Guarantee every customer to operate our equipment smoothly.

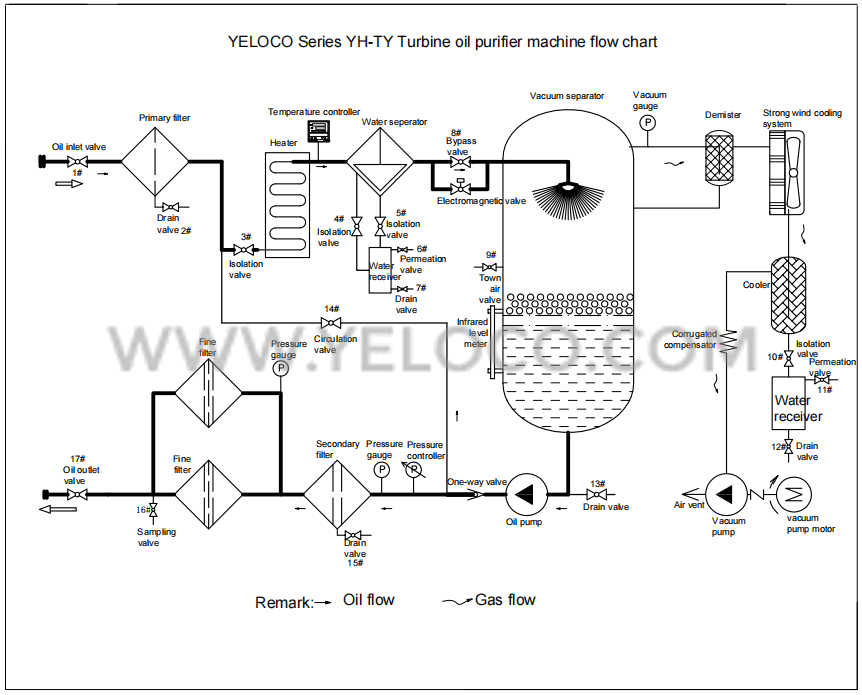

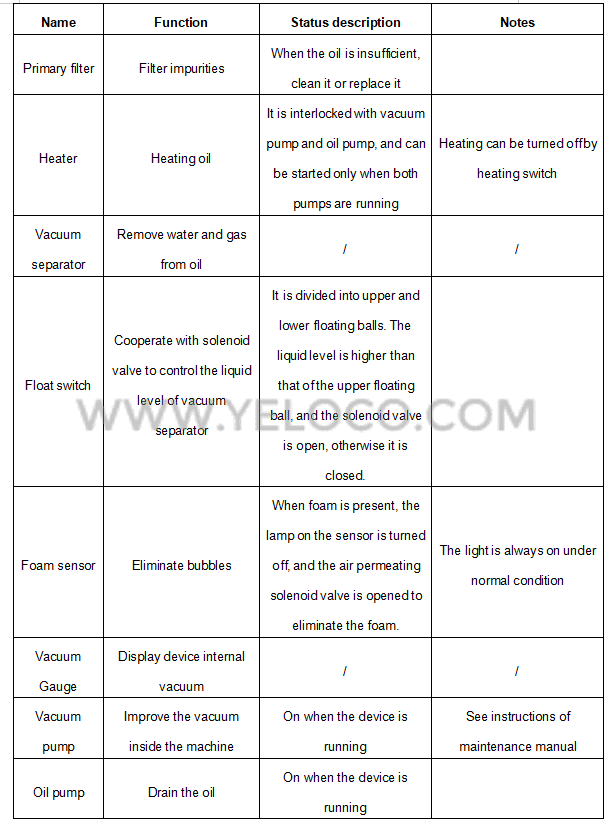

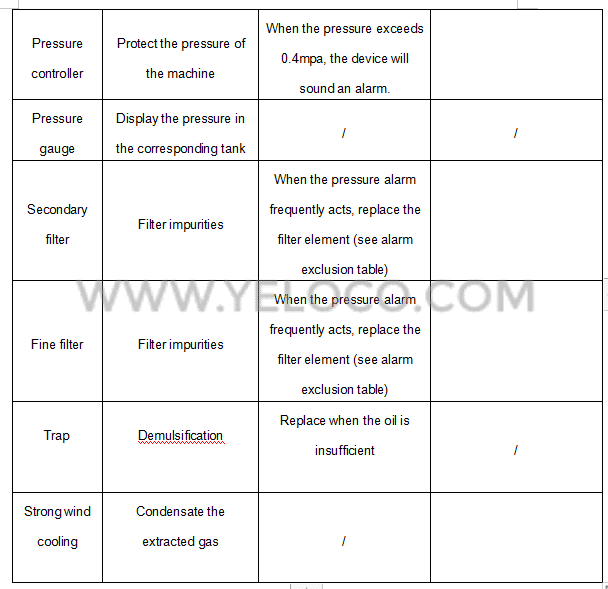

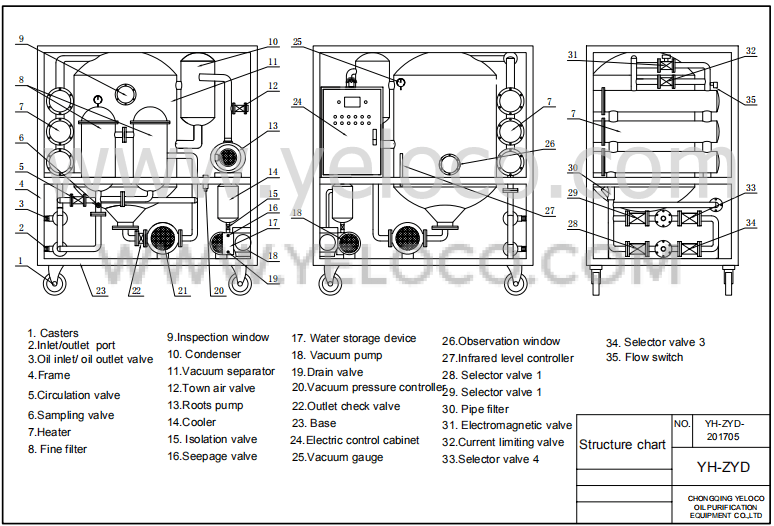

IV. Main Parts Function Of YELOCO Transformer oil filtering machine?

| Part name | Components | Functions |

| Coarse filter | Housing and filter element | Removing coarse mechanical impurities |

| Heater | Housing and heating tube | Heating transformer oil |

| Vacuum separation chamber | Housing, atomizer and separating tower | Removing water vapor and gas from oil |

| Condenser | Tabulation – axial flow fan | Condensing the harmful gas pumped by vacuum pump |

| Vacuum pump – Roots pump | Pumping up the separated harmful gases | |

| Oil Pump | Electric motor, coupling and oil pump | Transmitting transformer oil |

| Fine filter | Housing and filter element | Removing the mechanical impurities in form of coarse particles |

| Pipe valve | Controlling and providing transmission rout | |

| Electrical control system | LV apparatus, sensor, cabinet | Controlling work of electric motor, solenoid valve and heater |

V. Main Control Systems Of YELOCO Transformer oil filtering machine

1. Heating control system with Constant temperature:

The constant temperature heating control system consists of a programmable controller PLC, heater R, temperature sensor, etc. The PLC sends out a logic command through internal program calculation based on signals collected by the temperature sensor: when the temperature is lower than the set temperature, the heater R will start to work under the control of the PLC; when the temperature reaches the set temperature, the heater R will stop working based on the control of PLC; the above work will be repeated until the temperature is reduced below the lower limit set temperature, and thus the constant temperature heating control function is realized.

2. Automatic liquid level control system:

The automatic liquid level control system consists of a programmable controller PLC, a medium liquid level switch and an electromagnetic valve. The PLC sends a logic command through an internal program based on the liquid level signal collected by the medium liquid level switch: when the oil level is lower than the medium liquid level switch, the electromagnetic valve will start to work in a delayed manner; When the oil level reaches or exceeds the medium level switch, the solenoid valve will stop working immediately. Thus, the function of automatic liquid level control is realized repeatedly.

3. Over-pressure protection system:

The over-pressure protection system consists of a programmable controller PLC and a pressure switch P. The PLC sends out a logic command through an internal program based on the pressure signal collected by the pressure switch P. When the pressure exceeds a set value, the PLC will immediately send out an alarm signal and stop the product at the same time.

4. Oil injection protection system:

The oil injection protection system consists of a programmable controller PLC and a high liquid level switch. The PLC sends out a logic command through an internal program based on the liquid level signal collected by the high liquid level switch. When the high liquid level reaches, the PLC will immediately send out an alarm signal and stop the product at the same time.

5. Overload protection system:

The overload protection system consists of a programmable controller PLC, a motor protector QRF and a frequency converter VFF. The PLC collects an overload signal through the motor protector or the frequency converter and sends out a logic command through an internal program. When the overload signal is valid, the PLC will send out an alarm signal and stop the product immediately.

VI. How to Operate YELOCO Transformer oil filtering machine?

YELOCO Transformer oil filtering machine adopts PLC automatic controller, the operation is very simple.

1. Open oil inlet valve and oil outlet valve first. Turn the “Manual/ Automatic” knob switch to the “Automatic” position and press the “Start” button switch. See the below figure for the Manual/ Automatic operation diagram:

Under the control of the programmable logic controller PLC, the product will orderly control various motors, heaters, AC contactor and other components.

(The machine automatically works process as follows:

Start the vacuum pump → Roots pump will start to work automatically when the vacuum degree is lower than the set value → Oil inlet solenoid valve will start to work automatically when the liquid level in the vacuum separation chamber is lower than the liquid level switch → Oil outlet pump will start work automatically after the liquid level reaches the low liquid level switch → Heater will start to work automatically (and perform constant temperature control) until the sampling is qualified before entering the next process. )

2. Stop operation of Transformer Oil Purification Machine (Automatic method):

In the automatic operation state, press the “Stop” button directly, and the equipment will stop working orderly under the control of programmable logic controller PLC.

(The process as below: Stop heating → Delay for 5 minutes (adjustable) → Stop oil inlet solenoid valve → Stop Roots pump→ Stop vacuum pump → Stop oil outlet pump when low level switch detects that the liquid level is “None”.)

Please open below videos like to watch Transformer Oil Filtering Machine operation videos

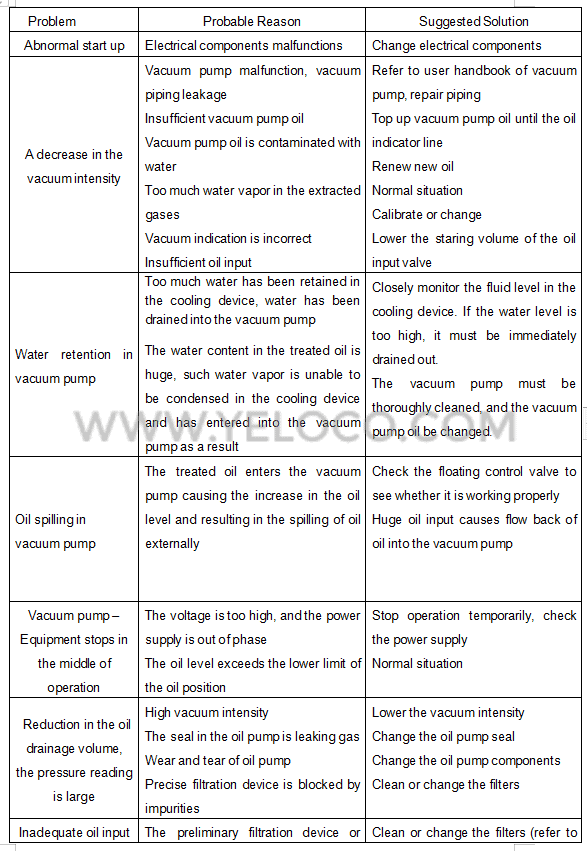

VII. How to Maintenance YELOCO Transformer oil filtering machine?

- When the vacuum pump is operating, the oil indicator must be closely monitored to have a firsthand information about the oil fluid condition. (the oil fluid shall be on the oil indicator line) When the water content in the vacuum pump oil is slightly on the high side, it must be immediately changed. (use the specialized vacuum pump oil, to decide on the renewal based on the visual inspection on the degree of contamination in the vacuum pump oil; if found to be degenerative and emulsified, it must be immediately changed) When there is a huge amount of water in the cooling device during operation, it must be instantly drained out.

- 2. The ever changing condition of the pressure values must be closely monitored at all times. When the pressure gauge is more than 0.35 Mpa, the filtering device must be washed and cleaned thoroughly or the filtering components must be changed; The primary filter and fine filter must be regularly removed and cleaned thoroughly to maintain adequate cleanliness in order to avoid blockages and cause the inadequacy in the oil input or the frequent operations of the oil pump.

- 3. For every 5,000 hours of operation, appropriate lubricants must be supplemented in order to prevent the overheating of the power equipment.

- 4. Regularly conduct checks on the operational conditions of the oil pump and the vacuum pump to avoid the sudden cessation of the equipment or severe condition of overheating. (refer to the user manuals of the oil pump and the vacuum pump)

- 5. After a certain period of operation for the equipment, conduct regular checks on the safety and reliability of the control system, the sensitivity and reliability of the temperature control device, the hardening effect of the seals in the pump shaft (leakage), the no blockage phenomenon of the piping system, the normal functionality on the pump and the related noise in the equipment. In the situation where the equipment has stopped operation for 1 month and above, this equipment shall be placed in a dry environment with its cabinet door properly closed and its main body suitably covered.

- 6. When the equipment is not operated, the residual oil shall be drained out completely.

VIII. On-site Projects

If you have any interesting, please contact us soon. sales@yeloco.com, Whatsapp: 0086 13647641182