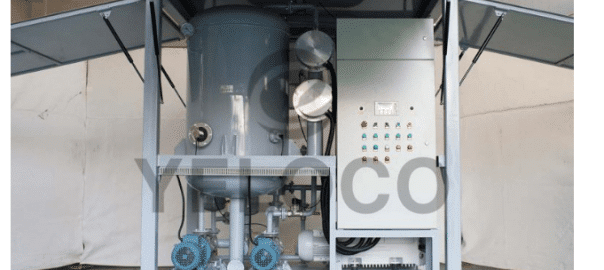

YELOCO Transformer Oil Regeneration Machine (Degassing + Dehydration + Fine filtration + Regeneration)

YELOCO Transformer Oil Regeneration Machine is capable of purifying and regenerating the below oils…

- Transformer oil

- Insulating oil

- Cable oil

- Dielectric oil

- Silicone oil

- Mutual Inductor oil

- Switchgear oil

The Series YH-ZYD-R Double-stage vacuum Transformer Oil Regeneration Equipment can rapidly remove the water content, gaseous matter and impurities found in a wide variety of oils, as well as the poisonous components in the oil fluid such as acetylene, hydrogen, methane, etc. in the insulating oil. This effectively enhances the insulating property of oil and ensures the normal operations of power installation, preventing the occurrences of incidents.

Furthermore, it can also satisfy the on-site installation or troubleshooting and maintenance and implement the vacuum suction for the transformer itself. At the same time, the Transformer Oil Regeneration Equipment is capable of completing the treatment of water and gas removal for the transformer oil, substantially shortening the oil treatment cycle.

It is widely used in a broad range of industries that include power plants, power stations, power companies, metallurgy, petrochemical, machinery, transportation, railways, and more, and is especially suitable for use in large scale voltage transmission and transforming equipment (350 KV – 1000 KV), as well as main national power grid transformers. Additionally, it can shorten the oil treatment cycle for the installation and troubleshooting/maintenance of the transformer.

Fulfilling the work implementation and commissioning specifications (Q/GDW 122-2005) of the national power grid transformers (350 – 1000 KV), oil immersed reactor and mutual inductors, it is also the top-choice equipment for use above the sea level of 500m.

The equipment can effectively remove moisture, gas and impurities from insulating oil, improve the compressive strength and quality of insulating oil, and regenerate deteriorated insulating oil. It can also remove deep oxides, free carbon and other polar substances from oil, and recover dielectric loss, oxidation resistance, acid-base water solubility and other comprehensive indicators of deteriorated insulating oil.

Previous attempts in manufacturing to address these issues saw the adoption of a Regeneration tank with silica gel, designed to absorb the oil acidity impurities and free carbon. However, the results weren’t positive, with more oil wasted during regeneration.

To address these issues, we have now developed the Regeneration filters. The Regeneration filter use resin filter and is based on an ion exchange principle, which absorbs acidic substances or metal ions in fluids, in order to reduce the acidity of fluids or increase the resistivity of oil.

Series resin regeneration filters adopt a large diameter structure and high filling capacity and have a very high contact absorption area and ability. The special high-performance ion exchange resin can purify oil quickly and efficiently. The acid-removing filter element can quickly and effectively reduce the oil acid value.

The acid-reducing capacity reaches 3.7 g molecular acid/liter. It is 5-7 times as powerful as ordinary diatomite and 2.5 times as much as activated alumina.

The oil acid value can reach below 0.1 mg KOH/g.

No metal ions were released in the treatment process, no gelatinous polyphosphate was produced, and no particle leakage pollution occurred.

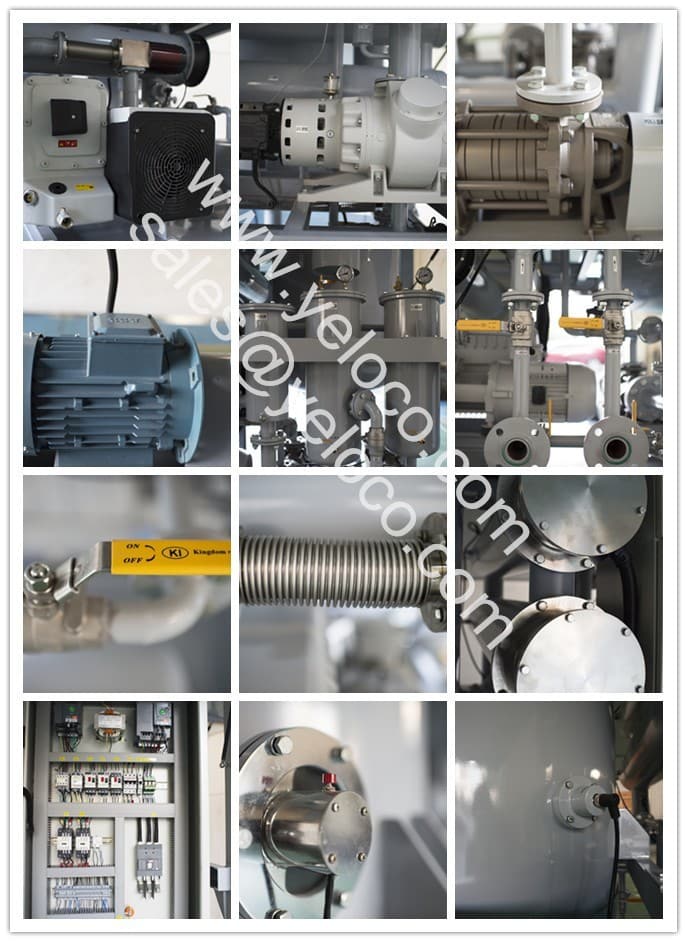

This equipment is designed with a powerful vacuum system.

Our company adopts rotary vane vacuum pump with a boots pump in the vacuum system (which can provide a higher internal vacuum impact and achieve a better dehydration effect). The vacuum separator adopts short-range distillation film evaporation technology, including short-range distillation technology, which can realize distillation and separation in the vacuum of 0.001 mbar and heating time of less than 1 minute. Therefore, for the substances with high boiling points and thermal sensitivities, it will undoubtedly become the preferred technology for distillation and separation.

Normally, the boiling point of a substance can be reduced by 20 to 50 degrees for reduction of pressure by one order of magnitude. Based on this, the boiling point of the substance at 0.001 mbar should be lower than its normal boiling point of 120 to 300 degrees. At present, short-range distillation technology can be applied to the distillation and separation of substances with a normal boiling point of close to 700 degrees. With the split branch node technology, water can quickly be evaporated in the oil. The design of polarization and the scientific vacuum pressure difference in the vacuum separator are more conducive to the escape of water and gas. With thin film evaporation technology and high vacuum, the system can completely and effectively remove oil, moisture and gas, so as to ensure the rapid separation of moisture content from insulating oil.

The equipment also possesses a precise filtration system.

The primary filter, which adopts a stainless steel mat-shaped net, is made of deep processing, with filtering accuracy of 80μm (optional), a large quantity of pollutants received and a long service life. It’s able to be repeatedly cleaned to reduce the intensity of the cleaning of the filter element.

The secondary filter is made of high-precision stainless steel mat-shaped net imported from Japan, which can be repeatedly cleaned, reducing the time required to unload and clean the secondary filter element and also improving the efficiency of the equipment.

The filtering accuracy is 10μm (optional). Precision filters, made of imported polymer filters from the United States, can effectively intercept impurities of various shapes in the oil. The machine adopts step-by-step encryption, proportionally sharing the impurity removal load of filter elements at all levels, and adopts reasonable fluid design to realize cleanliness and a deep filtration of fine particles in oil. The regenerative filter element adopts a kind of special high-efficiency oil purifier, which can purify and regenerate deteriorated insulating oil, remove acidic polar substances, suspended substances, and precipitated pollutants, as well as removing oil pigments.

For security, the device has multiple security protection systems.

The equipment is equipped with a perfect protection device. Through high temperature protection, over-pressure protection, power cut protection, over-voltage protection, under-voltage protection and phase-out protection of the equipment by various actuators, it can effectively ensure the normal operation of equipment and prevent any accidents from occurring.

The equipment is designed to be operated in a simple and convenient way. When you need to use the regeneration device it’s easily controlled by its control valve, which can be closed when not in use. The regeneration device can be manufactured separately and used in conjunction with the vacuum oil filter. It can also be used as a bypass in oil filter equipment. We have sold this machine for several years, with many customers experiencing high satisfaction with our machines.

![]()

![]()

![]()

![]()

Inquiry Now