Table of Contents

Chapter 1: Why need Turbine Oil Purifier machine?

The oil used for regulation and lubrication system of turbo-generator unit will be mixed with steam, water or impurities to different degrees during operation, which needs frequent maintenance and treatment, otherwise it may accelerate the deterioration of oil quality or cause the failure of regulation and protection system and the damage of bearing bush, thus affecting the safe operation of the unit.

Hazards of water, gas and impurities in turbine oil:

- The oil is rapidly oxidized and deteriorated to generate acidic substances, which corrodes the metal contact surface;

- Precipitation failure of additives in oil, reduction of lubricating film thickness and aggravation of mechanical wear;

- The insulation performance of oil decreases, the dielectric loss increases, and methane, acetylene and hydrogen increase;

- Lubrication, cooling and flow reduction accelerate metal surface fatigue;

- Ice crystals formed at low temperature block the components and reduce the rigidity of the system;

- Slow response of the system accompanied by irregular action conduction performance reduction;

- High oil temperature can not play a cooling role;

- The oil transfer pump and power equipment are damaged due to gas etching;

YELOCO Turbine Oil Purifier Machine, it can not only effectively remove gas, water and impurities in the oil, but also automatically demulsify, so as to achieve the real effect of purifying steam turbine oil. It improves the quality of oil products, ensures the normal operation of the regulation and lubrication system of the turbine units, and prolongs the maintenance cycle of the turbine units.

Chapter 2: Benefits of a Turbine Oil Purifier machine

1) Strong capabilities in filtering water less than 50PPM.

2) Fast demulsification less than 8 min.

3) Strong performance in purifying impurities less than 1 micron.

4) Excellent functions in removing gases less than 0.1%.

5) Advanced medium cooling and endothermic condensation system.

6) Highly-automated, compact and lightweight, reliable and safe. This facility adopts an infra-red liquid positioning automatic control device which has simple and reliable operation buttons.

The YH-TY series Turbine oil purifier machine is especially adaptable and suitable for handling turbine oil, hydraulic oil, refrigeration oil and other lubricating oils that require huge amount of water elimination and precise filtering functions.

Chapter 3: Parts of a Turbine Oil Purifier machine

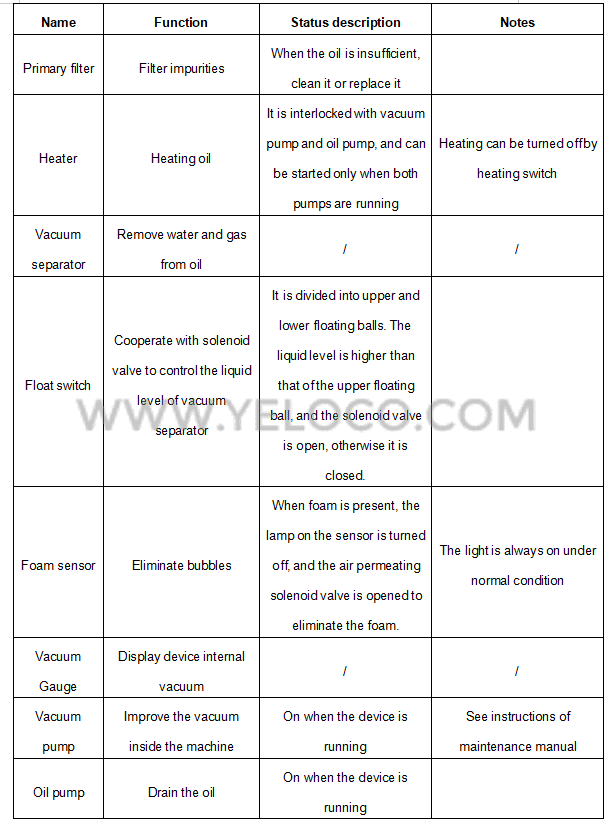

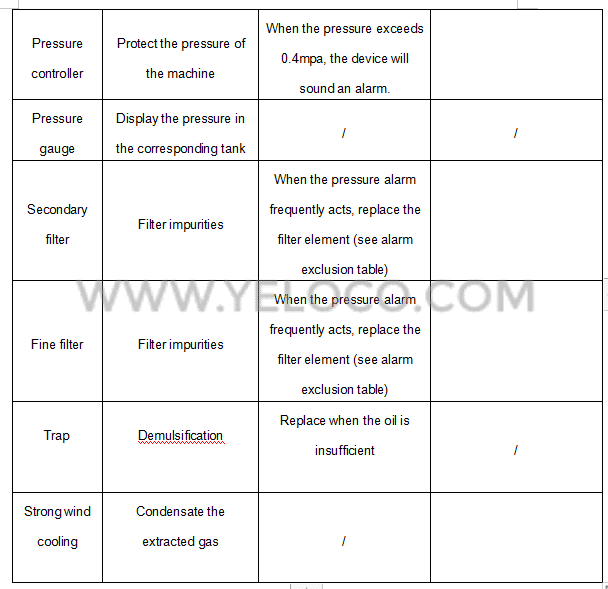

Chapter 4: How to operate Turbine Oil Purifier machine?

(1) Basic operation of start:

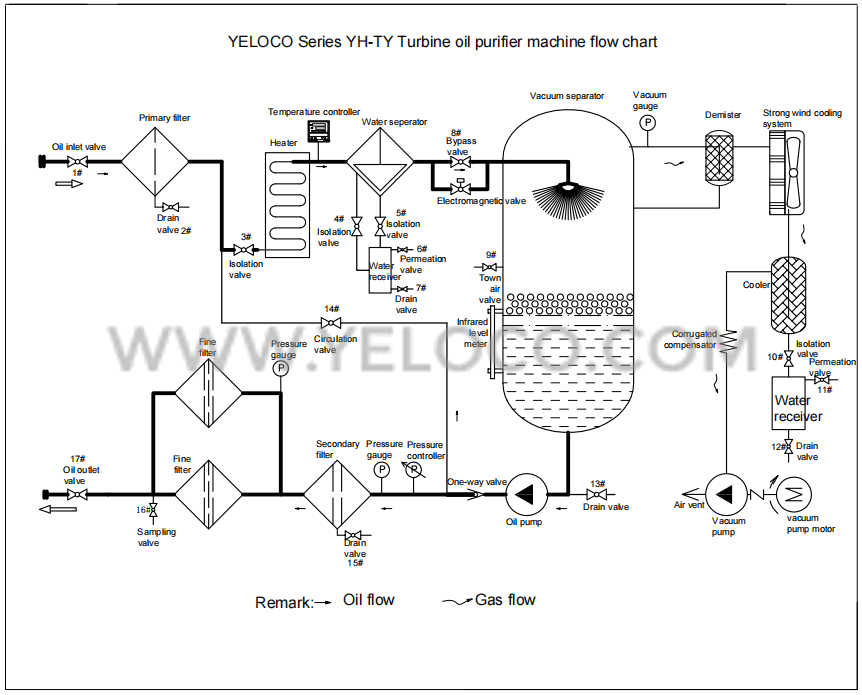

1) Open and close the relevant valves in accordance with the valve status function table, so that the oil circuit ( Oil inlet → Oil inlet valve → Primary filter → Heater → Water distributor (Trap)→ Oil supply solenoid valve → Vacuum separator → Oil pump → Secondary filter → Fine filter → Oil outlet valve → Oil outlet) is unblocked. Open oil inlet valve 1, oil outlet valve 12, block valve 4, block valve 5 and block valve 16. Close drain valve 2, bypass valve 3, bypass valve 9, circulation valve 10, air leakage valve 14, air leakage valve 17 and sampling valve 11, blowdown valve 18, air permeability valve 6, blowdown valve 7, blowdown valve 13 on the pipeline.

2) Switch the air switch QF and control switch QF1, and the power on indicator lamp HL on the panel is on.

3) Start the vacuum pump to start working, and the vacuum pump running indicator lamp is on.

4) The system starts to feed oil under the action of the oil inlet pump. When the oil enters the vacuum separator and reaches the control point of the upper liquid level, the oil pump will be automatically opened by sending a signal and the operation indicator lamp of the oil pump will be on at the same time.

5) Slightly open or close the control valve (outlet valve 12, inlet valve 1, circulation valve 10, bypass valve 3, bypass valve 9) in accordance with the specific conditions of working conditions to ensure the basic balance of oil inlet and outlet. That is to say, the oil level in the vacuum separator is always kept between the upper and lower liquid level gauge to avoid frequent start and stop of the oil pump; The circulation valve can be opened properly to reduce the pressure when the oil pressure is too high.

6) After the operation of vacuum pump and exhaust oil pump, if the oil temperature is lower than the set value of the temperature controller, the heater will be heated only after the heating knob is opened, and the heating indicator lamp is on at the same time.

7) In case of emergency during operation, press the emergency stop button SBE immediately to stop the machine; If you need to resume work, turn the emergency stop button left to reset, and the machine will start working again.

8) Observe the working condition of the vacuum separator at any time. If there is a large amount of foam in the vacuum separator due to the high moisture content of the oil, when the foam exceeds the liquid level gauge, the gas ballast valve shall be properly opened and the vacuum degree in the vacuum separator shall be maintained at about -0.085 MPa. Reduce the vacuum to eliminate foam, avoid oil spill, and close the gas ballast valve after the foam is removed.

9) The machine has a foam sensor. When the foam sensor senses the foam in the vacuum separator, it will automatically open the air permeating solenoid valve for defoaming. If there is still induction within the time set by the time relay (generally set to 0.5 s, see the attached figure, the setting of time relay), the machine will stop and alarm.

10) During the operation of the machine, personnel shall inspect the equipment, and the inspection period shall not be less than 30 minutes each time.

(2) Basic operation of Shutdown:

1) When the oil treatment is completed or the operation needs to be stopped

2) First, turn off the heating through the heater knob switch. After the oil purifier continues to run for 3-5 minutes, close the oil inlet valve.

3) Turn off the vacuum pump and stop vacuuming the machine.

4) Drain the oil in the vacuum separator through the oil pump, and then turn off the oil pump.

5) Close the inlet and outlet valves after the machine stops.

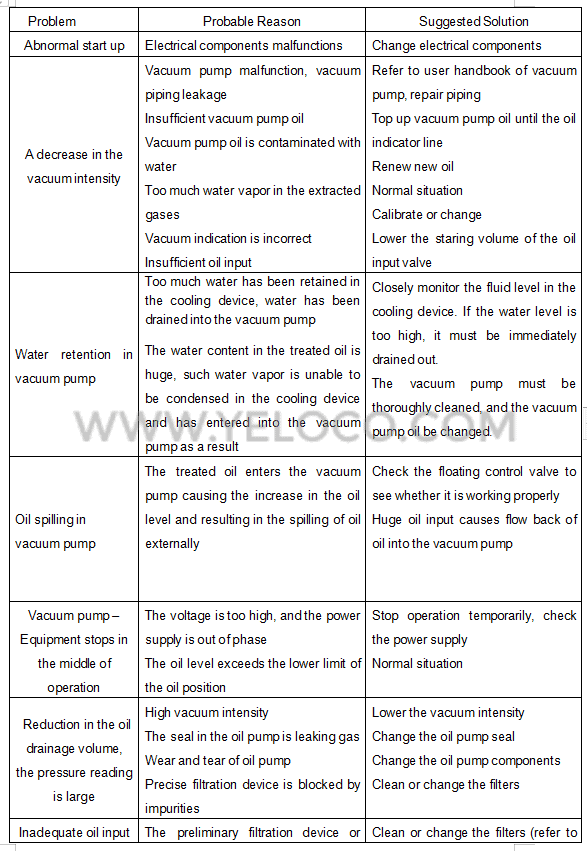

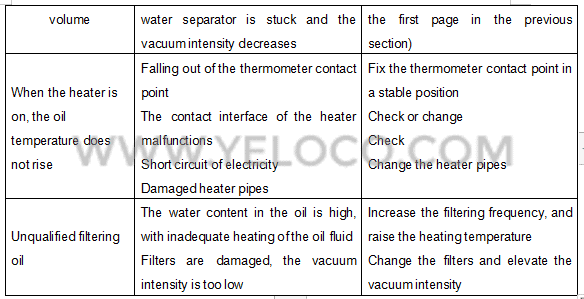

Chapter 5: Turbine Oil Purifier machine FAQ

If you have any inquiry in this machine, please contact us now!

FREE ACCESS

FREE ACCESS