Transformer Oil Filtration Machines – THE NEED:

Did you know that dissolved gasses present in transformer oil can result in arcing, corona discharges and overheating that will ultimately reduce the electrical efficiency and lifetime of the transformer? Not only this but, the insulation strength of the oil is also adversely affected by the water contamination that sometimes goes down to about 30 ppm (parts per million). This calls for a dire need to adopt Transformer Oil Filtration Machine well in time!

A transformer oil filtering can potentially shorten the duration by which you would require the oil to be treated during the installation and maintenance of the Transformer.

Let’s take a look at some of the functions, benefits, parts, types, design, installation process, quality checking, delivery packages, and other FAQS about the YELOCO Transformer Oil Filtration Machine.

Here’s how this guide is designed:

- Chapter 1: What is a Transformer Oil Filtration machine?

- Chapter 2: Benefits of a Transformer Oil Filtering machine

- Chapter 3: Parts of a Transformer Oil Purifier machine

- Chapter 4: Types of Transformer Oil Purification machine

- Chapter 5: Transformer Oil Filter machine Installation process

- Chapter 6: Transformer Oil Filtering machine use tips

- Chapter 7: How to package the Transformer Oil Filtration?

- Chapter 8: Transformer Oil Treatment machine FAQ

Chapter 1: What is a Transformer Oil Filtration machine?

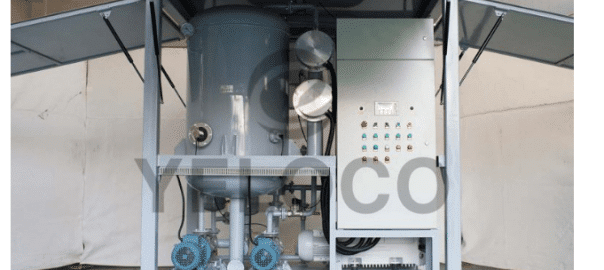

Do you know what a Transformer Oil Purification machine looks like? Well, it contains lots of smaller machinery components combined to make one big oil purifying solution. Here’s what it would typically look like:

![oil purification]()

You must be wondering how these oil purification work. Well, here’s a summary of the process:

YELOCO Transformer Oil Purification machine initially filters out the water, gas, impurities and acetylene, hydrogen, methane, etc. and other dangerous components in the synthetic oil in an attempt to improve the synthetic performance of the oil. This step effectively ensures the normal operation of the electrical equipment to minimize the occurrences of incidents.

While conducting the vacuum extraction, the oil purifier machine can also fulfill the installation or on-site inspection of the transformer. To further shorten the oil treatment cycle, the machine can also complete the operation of water separation and gas separation in the transformer oil.

Where is the machine typically used?

It is widely used in power generation plants, substations, power utility plants, metallurgical fields, railroad sectors, and other industries that require on-site transformer inspection in a large scale transformer power station which uses 110 kV or more, and the rapid treatment of synthetic oil such as new oil and imported oil. It is an equipment that is required on priority in areas where sea level is 500 m or above.

Chapter 2: Benefits of a Transformer Oil Filtering machine

So how can our YELOCO Transformer Oil Filtration machine benefit you?

1. It keeps the KV of your oil above the required level.

2. It removes explosive gas from the oil.

3. It removes moisture and impurities from oil thoroughly.

4. It increases the life of not only the transformer but also the oil.

5. It can perform the function of dehydrating the Transformer oil.

6. It can perform vacuum-pumping for the Transformer and vacuum-filling of oil for power transformer.

7. It can shorten the time to install and repair a power transformer.

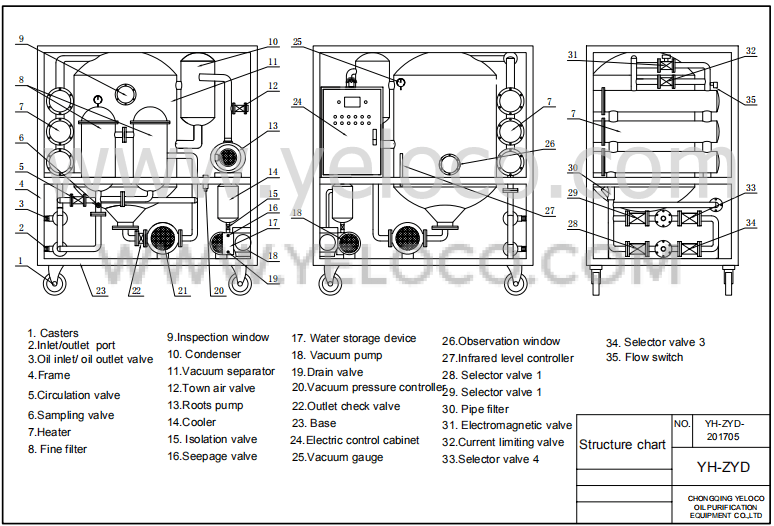

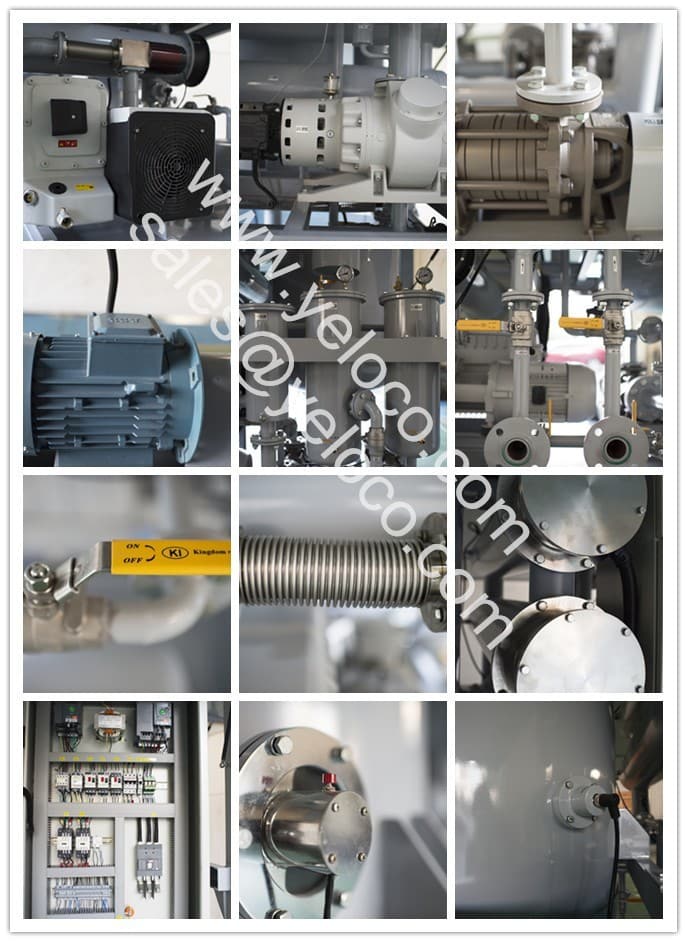

Chapter 3: Parts of a Transformer Oil Purifier machine

![]()

![]()

Chapter 4: Types of Transformer Oil Purification machine

According to the voltage level of the processing transformer, the oil filtration machine is classified as follows:

1. YELOCO Series YH-ZY High-vacuum Transformer Oil Purifier Machine. It is used for the treatment of a power transformer less than 110KV.

![Transformer oil filtering]()

2. YELOCO Series YH-ZYD Double-stage vacuum Transformer Oil Filtration Machine. It is used for the treatment of a power transformer more than 110KV.

![Transformer oil filtering]()

![]()

![]()

3. YELOCO Series YH-ZYD-U Ultra-high Voltage Transformer Oil Filtering Machine. It is used for the treatment of a transformer more than 330KV.

![transformer oil filtration]()

Chapter 5: Transformer Oil Filter machine Installation process

Follow our simple installation guide with a reference video, you’ll be just as good as a professional:

-

Place the equipment on the horizontal ground smoothly.

-

Connect the inlet and the outlet of the oil pipe and testing pipe properly.

-

Next, connect all power cables.

-

Turn the “Manual/ Automatic” knob switch to the “Automatic” setting and press the “Start” button switch. Under the control of the programmable logic controller PLC, the machine will work automatically.

-

Press the “Stop” button directly, and the equipment will stop working orderly under the control of programmable logic controller PLC.

There you go. Wasn’t that simple? It’s as safe as it sounds too!

After every set of oil filtration machine prepares well, we will make operation vides for customer reference.

Chapter 6: Transformer Oil Filtering machine use tips

These tips are used for all kinds of vacuum Transformer Oil Purifier machines. As a long-established brand in China, YELOCO, an oil filtration machine company, has had over 20 years of industrial credibility and integrity. The following tips will help you operate the vacuum Oil Purifier machine correctly and increase the life of not only the Transformer but also the oil.

-

Oil can only be circulated inside the transformer at 1,500 l/per hour. You can open ¾ of the oil outlet valve as well as the machine circulation valve to control oil flow capacity when you are filling oil into the Transformer.

-

Transfer of oil from one tank to another tank can be done at more than 1,500 L/per hour.

-

Oil should be circulated through machine filters more than once (twice is preferred) for better cleaning.

-

Oil should not be heated above 60 degrees Celsius. The maximum suggested temperature is 65 degrees.

-

If the oil going into the vacuum chamber is too hot, it will boil and overflow. Therefore, YELOCO sets the machine heating temperature to 60 degrees Celsius.

-

Oil going into the machine should be restricted at the source so that it prevents the machine from over-filling. This would mean that the machine vacuum chamber volume must match machine flow capacity. YELOCO Oil Purifier Machine’s design and make it according to these scientific ratios.

-

Dirty oil will need to be circulated slower so that the machine can withdraw moisture and prevent machine overflowing.

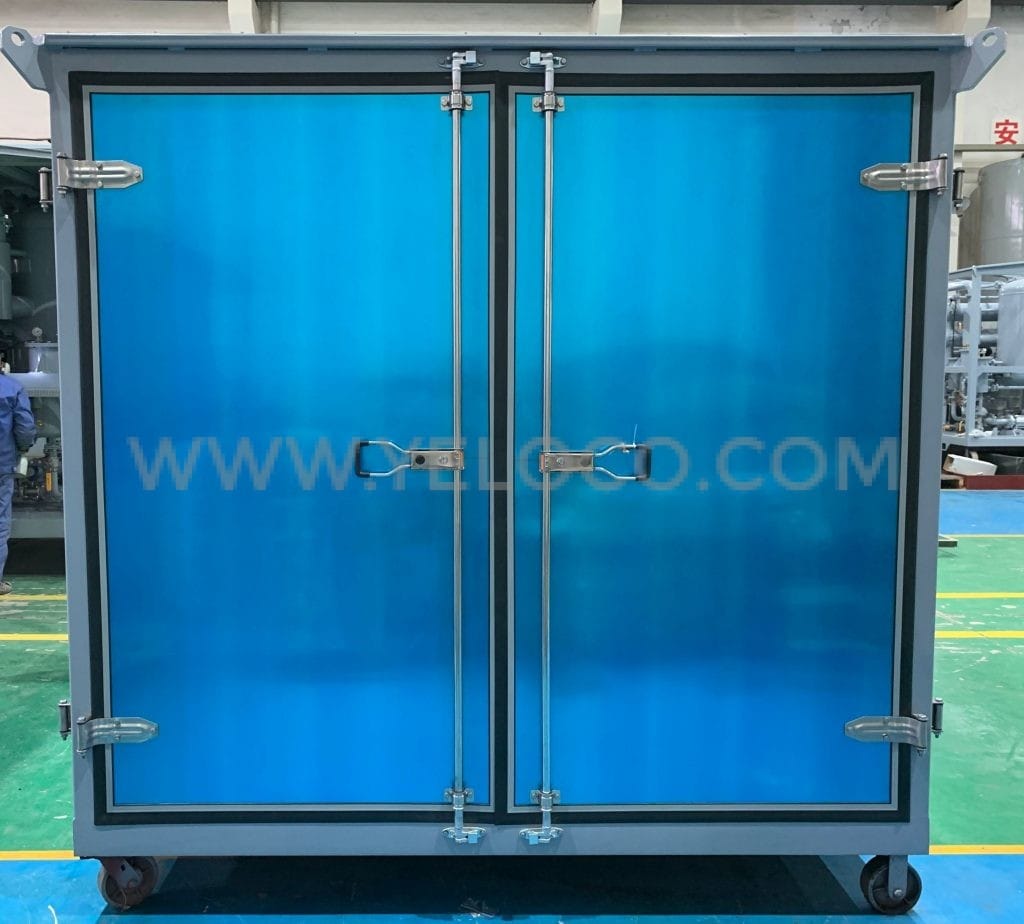

Chapter 7: How to package the Transformer Oil Filtration?

![Transformer oil filtration]()

Why are tin cases used? Well take a look at the following advantages:

-

Iron box packaging acts as an excellent barrier and provides comprehensive protective properties to the machine. These packaging materials have extremely low (almost zero) permeability to gas, water, and water vapor, good fragrance retention, and are completely opaque and effective. The same properties also avoid the harmful effects of ultraviolet rays from permeating inside the package. Plastics and paper packages do not match these properties for transporting and carrying such huge machines. Therefore, iron box packaging can provide excellent protection for the contents and is conducive to maintaining the quality of the goods for a long time.

-

Iron box packaging has good mechanical properties and carries high strength. This type of packaging also has good ductility and high strength. They can be processed by stamping, rolling, stretching, welding, etc., and can be made into thin walls. Packaging containers that have high compressive strength and are not easily damaged and can also be combined with other materials to form composite packaging materials with excellent comprehensive performance.

-

The packaging is convenient and hygienic. Its containers and internal coatings can generally meet the requirements of hygiene and safety and can adapt to different climatic conditions. The waste from this packaging is better treated and can be recycled.

Chapter 8: Transformer Oil Treatment machine FAQ

1.The oil inlet volume is small and the liquid level balance for normal operation of oil purifier can’t be sustained:

|

Reasons for faults

|

Repair method

|

|

Oil inlet valve is damaged

|

Replace oil inlet valve

|

|

The coarse filter element is blocked

|

Clean or replace the coarse filter element

|

|

Solenoid valve is damaged

|

Replace solenoid valve

|

|

Gas leakage between the oil tank and oil inlet

|

Check and repair

|

2.1 The product is subject to shutdown with alarm, shutdown for excessively high liquid level

|

Reasons for faults

|

Repair method

|

|

Solenoid valve element is blocked

|

Check and restore the valve element

|

|

The water content in the oil is too high, and a large amount of foam appears in the vacuum separation chamber T3.1.

|

Reduce vacuum degree a little. After a large quantity of water content is removed, restore high vacuum degree

|

|

Low liquid level switch fails

|

Replace liquid level switch

|

|

Leakage between oil tank and oil inlet

|

Check and repair

|

|

After the fault is repaired, the machine can’t work normally again until the oil fluid in T4.1 is drained out fully.

|

2.2 Shutdown because of over-pressure

|

Reasons for faults

|

Repair method

|

|

Fine filter element is blocked

|

Check and restore the valve element

|

|

Outlet oil valve is closed for error operation

|

Check and open the oil valve

|

|

Outlet oil valve is damaged

|

Replace the oil outlet valve

|

3. The noise of the oil pump rises suddenly

|

Reasons for faults

|

Repair method

|

|

The oil liquid level in the vacuum separation chamber is too low

|

Repair based on fault 1

|

|

The vacuum separation chamber is full of foam

|

Reduce vacuum degree a little. After a large quantity of water content is removed, then restore a high vacuum degree

|

4. The equipment shuts down suddenly

When the equipment stops suddenly due to power failure during operation, it is necessary to close the oil inlet and outlet to prevent the oil being from being sucked back into the vacuum separation tank and then into the vacuum pump. Thus, contaminating the vacuum pump.

If you have any other interesting points to share, please feel free to leave a quick message below.

Inquiry Now