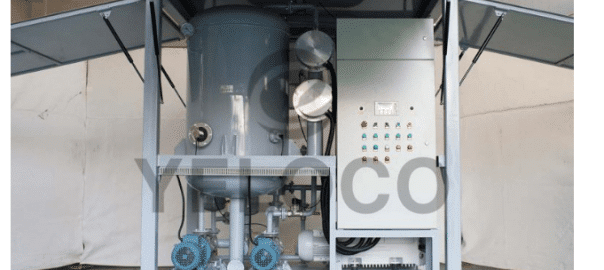

What is the function of YELOCO Hydraulic oil purifier machine/ Lubricating oil purification machine?

The series YH-TYA Hydraulic oil purifier machine/ Lubricating oil purification machine is widely applied to power, metallurgic, mine, mechanical, chemical and manufacturing industries for purification of hydraulic oil, freezing machine oil, gear oil, vacuum pump oil, gas engine oil and heat treatment oil.

I. Why these oil need use YELOCO Lubricating Oil Purification machine/ Hydraulic oil filtering machine?

1) Water and gas are in two forms in the oil – dissolved water, gas (below the saturation point) are present in most oil systems and oil equipment, and free water, gas (above the saturation point) is present in many oils.

2) Due to system leakage, poor sealing, long-term thermal load of oil, open storage, etc., moisture and gas in the air settle in the oil, resulting in water and gas in the oil.

3) As the system leaks, the dust in the air enters the system and the dust falls off. The oil works for a long time under high temperature and water. It will inevitably cause some oil to crack and precipitate the gelatinous substance.

What are harms of water, gas and impurities in the lubricating oil?

·Rapidly oxidize and degrade the oil to form acidic substances and corrode metal contact surfaces

·The precipitation of the additive in the oil fails, the thickness of the lubricating film is reduced, and the mechanical wear is increased

·Lubrication, cooling, and reduced flow properties accelerate metal surface fatigue

·Ice crystals formed at low temperatures block components and reduce system rigidity

·System response is slow and accompanied by irregular motion conduction performance degradation

·Higher oil temperature does not cool

·Oil pump and power equipment are damaged by cavitation.

II. YELOCO Hydraulic oil purification/ Lubricating oil filtering machine function

The Series YH-TYA Hydraulic oil purifier/ Lubricating oil filtering system filters out the water, gas, impurities and volatile matters, (methanol, ethanol, acetylene, hydrogen, methane, ammonia) etc. and other dangerous components in the oil, etc. further raising the quality of the oil fluid, restoring the viscosity, cleanliness and performance of the various oils. Additionally, it effectively ensures the normal operation of the usage of the turbine oil, substantially reduces the occurrence frequency of frictions, elevating the lubricating performance, and avoid the occurrence of any potential incidents.

III. How to treatment these oil?

1) When the Hydraulic oil purification machine/ Lube oil purifier machine is in operation, the oil fluid will first of all flow into the heater under the effect of differences in internal and external pressure of the oil fluid to conduct heat exchange so that the oil fluidity is further enhanced and the water content in the oil fluid is evaporated in the vacuum separator.

2) After the heating process, it will enter into the preliminary purification device to remove the large molecules of impurities.

3) Thereafter, the oil fluid will now enter into the water separator. As the water separator uses an enhanced hydrophilic and hydrophobic technology, it comprehensively alters the interactive performances of the 2 interfaces between oil and water, enabling the microscopic water molecules to accelerate their activities and integrating into a larger water molecule that is big enough to be separated from the oil fluid. The extracted water molecules will settle down on a collection device and be emptied out.

4) The oil fluid will continue to move into a customized and personalized vacuum separator, whereby it capitalizes on the molecular separation principle to execute pressure-changing resolution, vacuum retention, rapid three-dimensional evaporation, and elimination of molecular bonding so that the dissolving water, dissolving gases, and the free gases will quickly break free from the oil molecules and be filtered out. They will first form into the vapor state in the vacuum separator, and then later form into the membrane state so that the contact surface is a few hundred times that of the original in the vacuum, and the water content in the oil will evaporate and be pumped out of the vacuum system under extreme high temperature, highly intensified vacuum, large surface area and high-speed pumping.

5) The dry oil fluid that has been vaporized and eliminated of the water content in the vacuum, will remove the microscopic molecules of impurities in the oil fluid after being pumped into a more precise filtering device through the oil drainage pump, thereby completing the whole process of oil purification.

If you have any interesting, please contact us now. Email: sales@yeloco.com, whatsapp: 0086 13647641182.